Metallographic Replicas

Most of materials damage mechanisms could be successfully diagnosed through carefully

examination of field metallographic replicas.

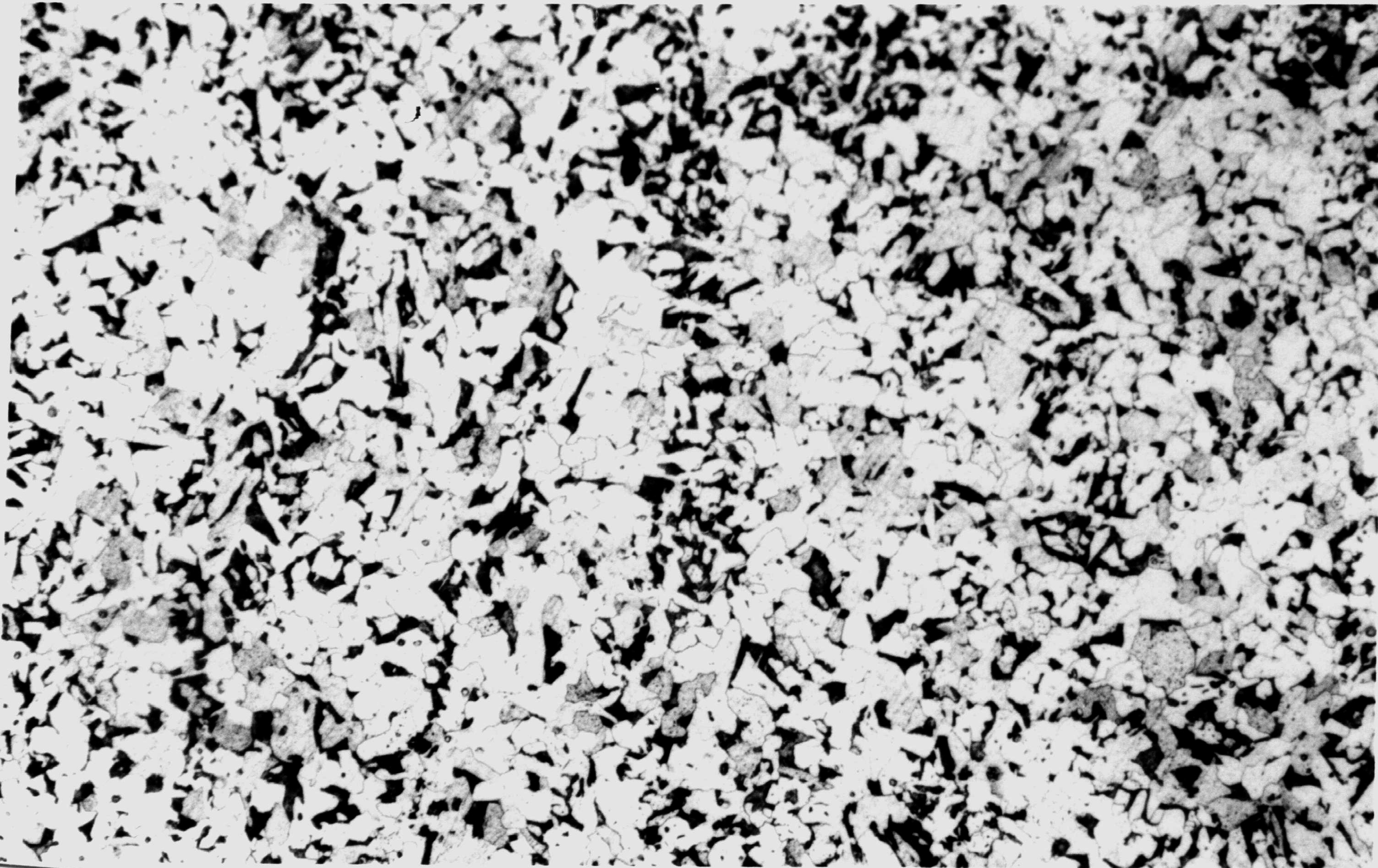

The parent image corresponds to a classical ferritic-perlitic low carbon steel (0.2 to 0.3% C).

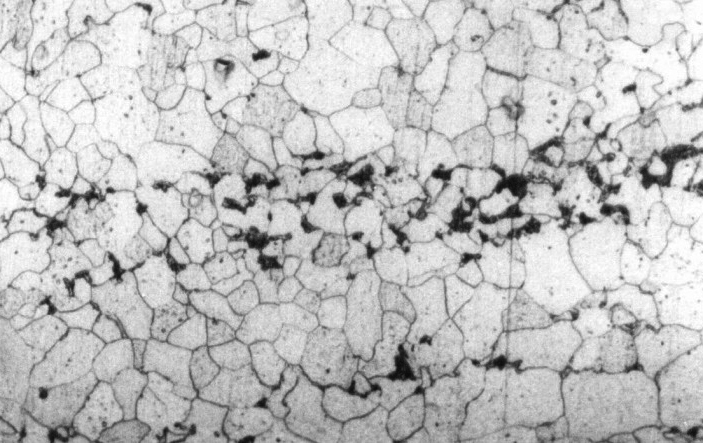

Decarburization

Some atmospheres together with exposure to high temperatures (as in creep range) could affect

the intrinsic perlitic or bainitic structure of steels, with the associated lost of

mechanical properties and creating conditions for different types of subsequent

damage mechanisms in the material.

This damage mechanism can be easily detected by means of metallography.

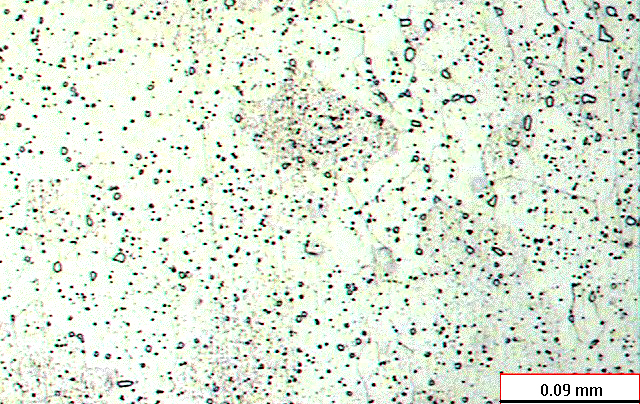

Spheroidization

Carbides spheroidization is a another damage mechanism that can be observed

using metallograpic field replicas.

In the case of materials used at high temperatures,

spheroidization must be avoided because it leads to a decrease in the mechanical properties

increasing plastic deformation via creep mechanisms with the subsequent failure of components.

Microcracking

Material cracking can be produced from very different reasons, these failure mechanisms can

be detected at early stages through field metallography.

Hydrogen damage, Stress Corrosion Cracking, eutectic phased at

grain boundary are some of the possible causes of microcracking